The difference between impeller of centrifugal pump and the difference between open impeller of closed impeller

The impeller is the work part of the centrifugal pump, and it is one of the important parts of the centrifugal pump depending on its high speed rotation to the liquid to do the work of the liquid. Health level self-priming pump

The difference of centrifugal pump impeller:

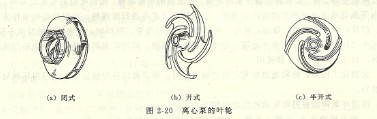

(1) the impeller of the classified impeller is generally composed of three parts of the hub, the blade and the cover plate. The impeller cover a front cover plate and a back cover points, called impeller entrance side of the front cover, the cover plate on the other side is called back. In the form of structure, the impeller can be divided into three kinds.

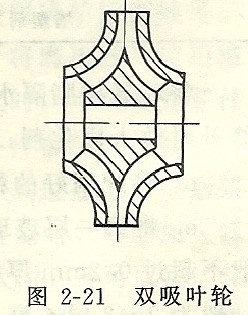

(1) there are cover plates on both sides of the closed impeller impeller and 4~6 blades between the cover plates, as shown in Figure 2-20 (a). When the bending direction of the blade is opposite to the rotation direction of the impeller, it is called the shield and bending blade. The blades of the general impeller are all back bending blades. This kind of closed impeller is of high efficiency and wide application, and is suitable for conveying clean liquid containing no solid particles and fibers. The closed impeller has two types: single suction and double suction (Figure 2— 21). The double suction impeller is larger than the single suction impeller.

2. There are no cover plates on both sides of the open impeller, and the blades are connected to the hub through the stiffeners, as shown in Figure 2-20 (b). This kind of impeller is simple in structure, easy to manufacture, but low in efficiency. It is suitable for transporting liquid containing more solid suspension or fiber.

The semi open impeller the impeller hub only, as shown in Figure 2-20 (c) shows. It is suitable for transporting liquid which is easy to precipitate or contain solid suspension, and its efficiency is between the open type and the closed impeller.

According to the shape of impeller and the flow direction of liquid in impeller, impeller can be divided into radial flow, axial flow and mixed flow. Radial impeller is applied in centrifugal pump, and liquid enters the impeller along the axial direction, and flows out of the impeller along the radial direction. The energy obtained by the liquid is mainly derived from the centrifugal force produced by the rotation of the impeller. Axial flow impeller is applied in axial flow pump, and the liquid is axial through impeller. The energy gained from liquid is mainly derived from lift force (i.e. thrust) generated when impeller rotates. The mixed flow impeller is applied in the mixed flow pump. The liquid enters the impeller along the axial direction, and flows along the direction between the axial and the radial direction. The liquid is transported by the mixing action of centrifugal force and axial thrust.

According to different needs, the impeller can be made of cast iron, cast steel, stainless steel, glass steel, plastic plea and other materials. Method of manufacturing impeller with foundry casting and precision casting, welding, molding, affect its size, shape and manufacture precision on pump performance.

- Close This Page

- Recommendation:

- Browse: