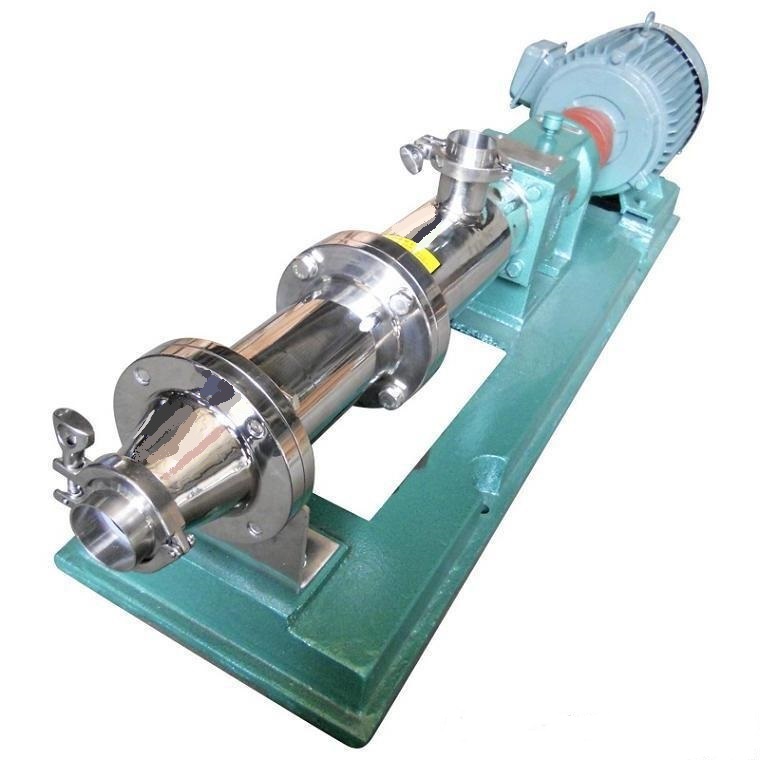

Health class single screw pump product overview:

Sanitary pump is a rotating mesh volume by circumventing the work principle, the main working parts are eccentric screw (rotor) and fixed lining (stator). Due to the special geometry of the two parts, a separate sealed cavity is formed. The medium is uniformly driven by the axial flow. The internal flow velocity is low, the volume is kept constant and the pressure is stable, so there will be no eddy and agitation. The output pressure of each level pump is 0.6MPa and head 60m (clean water). It is suitable for the temperature of the conveying medium below 80 C (special requirements of up to 150 C). Because the stator is made of many kinds of elastic materials, so this pump has the characteristics that the pump is not suitable for the transportation of high viscosity fluid and the transportation of rigid suspended particles or fiber containing medium. The flow rate is proportional to the speed. Transmission can be driven directly by a coupling, or variable speed motor, triangular belt, transmission and so on. This pump has few parts, compact structure, small size and easy maintenance. The rotor and stator are easy to wear, simple in structure and easy to install and dismantle.

Health class single screw pump product overview:

Sanitary pump is a rotating mesh volume by circumventing the work principle, the main working parts are eccentric screw (rotor) and fixed lining (stator). Due to the special geometry of the two parts, a separate sealed cavity is formed. The medium is uniformly driven by the axial flow. The internal flow velocity is low, the volume is kept constant and the pressure is stable, so there will be no eddy and agitation. The output pressure of each level pump is 0.6MPa and head 60m (clean water). It is suitable for the temperature of the conveying medium below 80 C (special requirements of up to 150 C). Because the stator is made of many kinds of elastic materials, so this pump has the characteristics that the pump is not suitable for the transportation of high viscosity fluid and the transportation of rigid suspended particles or fiber containing medium. The flow rate is proportional to the speed. Transmission can be driven directly by a coupling, or variable speed motor, triangular belt, transmission and so on. This pump has few parts, compact structure, small size and easy maintenance. The rotor and stator are easy to wear, simple in structure and easy to install and dismantle.

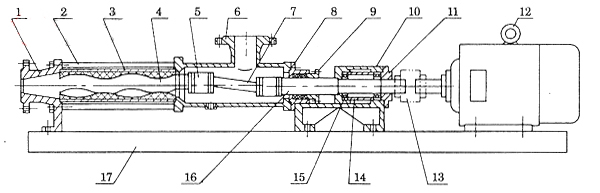

1 | 出料口 | 4 | 螺杆轴 | 7 | 连节轴 | 10 | 轴承座 | 13 | 连轴器 | 16 | 传动轴 |

2 | 拉杆 | 5 | 万向节总成 | 8 | 填料座 | 11 | 轴承盖 | 14 | 轴套 | 17 | 底座 |

3 | 定子 | 6 | 吸入口 | 9 | 填料压盖 | 12 | 电动机 | 15 | 轴承 |

Health class single screw pump product overview:

Sanitary pump is a rotating mesh volume by circumventing the work principle, the main working parts are eccentric screw (rotor) and fixed lining (stator). Due to the special geometry of the two parts, a separate sealed cavity is formed. The medium is uniformly driven by the axial flow. The internal flow velocity is low, the volume is kept constant and the pressure is stable, so there will be no eddy and agitation. The output pressure of each level pump is 0.6MPa and head 60m (clean water). It is suitable for the temperature of the conveying medium below 80 C (special requirements of up to 150 C). Because the stator is made of many kinds of elastic materials, so this pump has the characteristics that the pump is not suitable for the transportation of high viscosity fluid and the transportation of rigid suspended particles or fiber containing medium. The flow rate is proportional to the speed. Transmission can be driven directly by a coupling, or variable speed motor, triangular belt, transmission and so on. This pump has few parts, compact structure, small size and easy maintenance. The rotor and stator are easy to wear, simple in structure and easy to install and dismantle.

- Close This Page

- Recommendation:

- Browse: